High tech minerals refer to rare metals and non-metallic minerals with special properties that are widely used in strategic emerging industries. They are used to produce precision high-tech products and environment-friendly products under the condition of low-carbon economy. They have special strategic significance for high-tech development, play a key role in national strategic emerging industries and economic development, and occupy the leading position of scientific and technological innovation To maintain the economic competitiveness of a country or region. Different countries have different standards for the definition of high-tech minerals. There are 35 kinds of high-tech minerals defined in China, including rare earth, rare earth, rare scattered minerals, platinum group elements, other metals and non-metallic minerals such as boron, graphite, fluorite and high purity quartz.

Boron

Boron is an important rare and non-metallic element with a content of about 0.001% in the crust. Boron is not only a necessary micronutrient for higher biology, but also has a series of excellent physical and chemical properties, such as light weight, high hardness, flame retardant and heat resistance, wear resistance, catalysis, non magnetism, etc.

In nature, boron mainly occurs in the form of borosilicate minerals, boroaluminosilicate minerals and borate minerals, such as brucite, xonotlite, nabrolite, bornite and natural borax. Boron ore is an important raw material of boron fiber, alkali free glass, functional ceramics, boron nitride and anti nuclear radiation functional materials, which plays an important role in national defense security and war new industry.

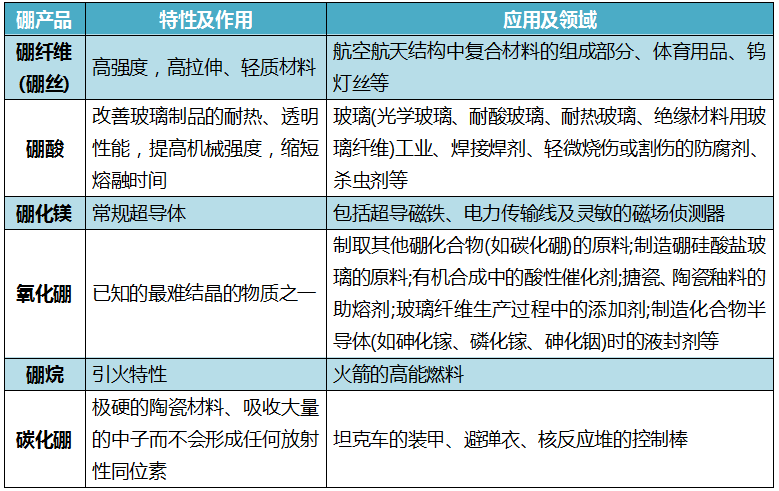

Classification and application of boron products

Due to the special functions of boron and boron compounds, boron has been on the stage of material industry from the original role of raw material. Boron is widely used in the new generation of electronic products, clean energy, new materials, new energy automobile industry and modern agriculture, resulting in new growth points. For example, graphene is a good conductor, which is likely to develop new nano materials and has a wide application prospect.

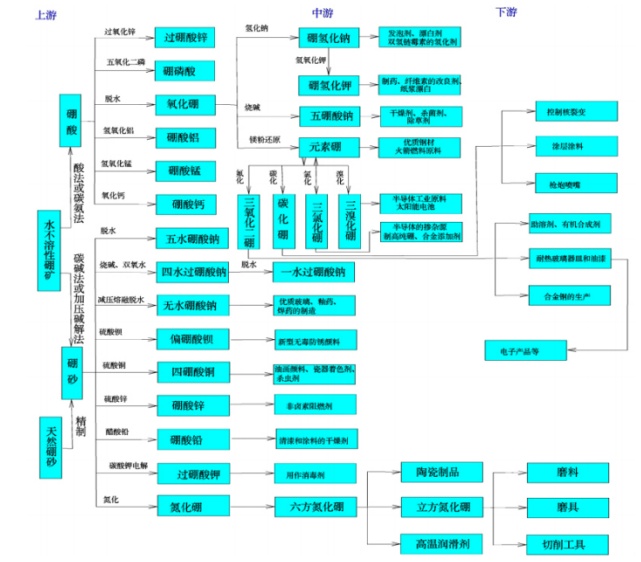

Schematic diagram of boron industry chain

In addition, boron ore is in short supply. The global boron reserves are about 150 million tons. China’s Boron reserves rank second in the world, but only account for 6.8% of the world’s proven reserves. The exploration level is not enough, and there are relatively few high-quality boron resources available for development and utilization. Therefore, in the future, we should strengthen the investigation, evaluation and exploration of volcanic sedimentary high-quality boron deposits, promote the upgrading of China’s boron industry, optimize the structure and layout of development and utilization, strengthen technological innovation, promote the comprehensive development and utilization of resources, close international cooperation, promote the import of high-quality boron raw materials, and ensure the supply of boron resources.

graphite

Graphite has excellent characteristics of high temperature resistance, corrosion resistance, heat conduction and conductivity. It is the raw material for processing graphene, lubrication, sealing, conductivity, adsorption, ultra-high temperature electrode, fire resistance, synthetic diamond, nuclear material, lithium battery and super capacitor and other functional materials and key basic materials. It plays an important role in the national war new industry, economic security and national defense security, and is known as “Strategic resources to support the development of high and new technology in the 21st century”.

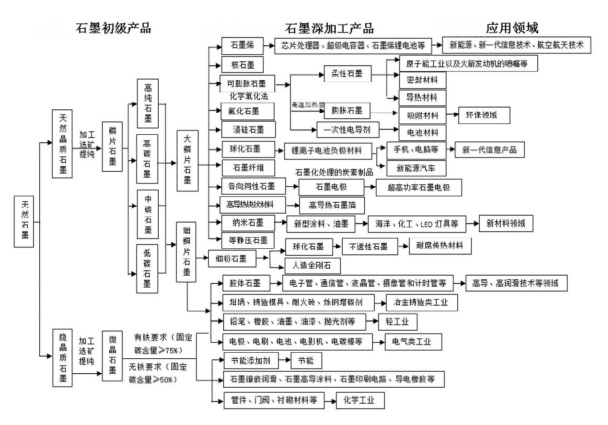

Flow chart and application field of fine processing of graphite products

Graphite is the dominant mineral in China, accounting for 65% of the global output. China attaches great importance to the protection, development and utilization of graphite resources, and has carried out a series of deployment. For example, graphite is listed as the strategic focus of new material development in the 13th five year plan, crystalline graphite is listed in the list of strategic minerals in the national mineral resources plan (2016-2020), and graphite and carbon products are included in the electronic core industry, cutting-edge new materials, new energy industry and energy saving industry in the new generation of information technology in the classification of strategic emerging industries (2018) issued by the National Bureau of statistics Energy, sealing, thermal insulation materials, new energy materials manufacturing and other fields further highlight the importance of graphite.

Application fields of graphite and its products in the classification of strategic emerging industries(2018)

In the past, graphite consumption used to be concentrated in refractory and casting fields for a long time, but with the peak of China’s steel consumption, the growth rate of graphite consumption slowed down. In the future, the consumption of graphite will shift from traditional refractory materials, steel-making, pencils and other fields to new energy and new materials such as lubricating materials, brake lining friction products, graphite products and so on. The consumption of graphite high-end material grade products such as high-purity graphite, spheroidized graphite and graphite fluoride will increase rapidly in strategic emerging industries such as new energy vehicles, energy storage, nuclear energy, electronic information and aerospace technology.

Fluorite

Fluorite, mainly composed of calcium fluoride (CaF2), is the world’s most important supplier of mineral raw materials for fluorine resources, known as the “second rare earth”. It is widely used in new energy, new materials and other strategic emerging industries, as well as refrigeration, building materials, smelting, optics, ceramics, glass, national defense, electronics, military and other fields.

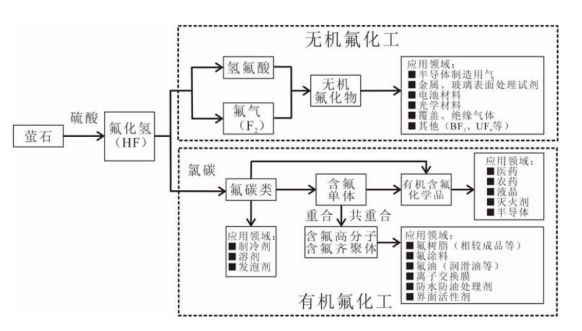

Fluorite industry chain

In the traditional building materials, metallurgy and other fields, the demand for fluorite has crossed the peak and began to decline or tend to be stable. With the development of new materials, new energy and other strategic emerging industries to the height of national strategy, the demand of fluorite in strategic emerging industries has become the key to dominate the demand trend of fluorite in China.

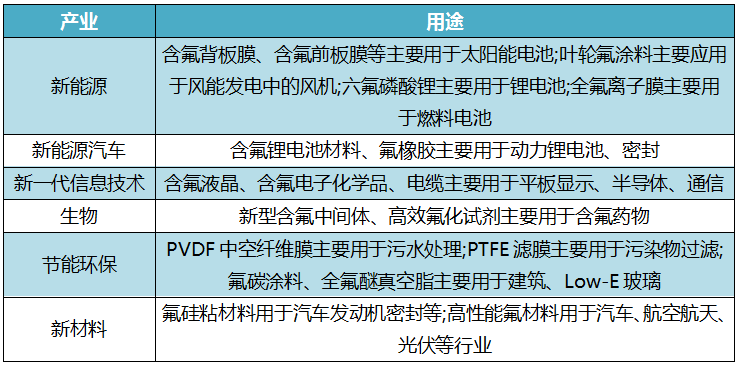

Application of fluorite in strategic emerging industries

It is estimated that the demand for fluorite will continue to grow in the future, and the demand for fluorite in China will reach 5.679 million tons in 2030. It is suggested to increase the exploration investment to ensure the future demand; at the same time, develop the fluorine chemical industry, strengthen the technical research of high-end products and environmental protection products, and develop to fine and lightweight products, so as to upgrade from a big fluorine chemical industry country to a powerful fluorine chemical industry country.

High purity quartz

High purity quartz refers to the natural quartz mineral raw materials that can purify and process high-end products of high purity quartz with SiO2 purity greater than 99.998% (4n8). High purity quartz high-end products are raw materials for the production of functional materials and key basic materials such as chip industry (semiconductor), new energy (photovoltaic, etc.) and silicon industry, and play an important role in national strategic emerging industries, economic security and national defense security.

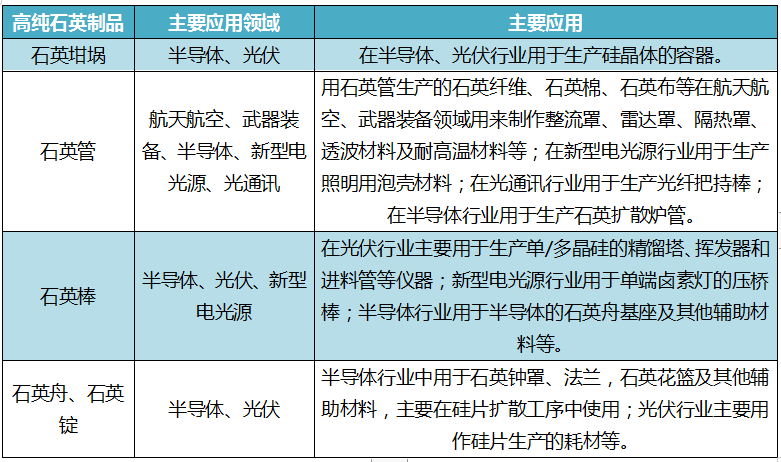

Main application fields of high purity quartz products

With the gradual advancement of made in China 2025 and the continuous development of strategic emerging industries, China’s demand for high purity quartz is increasing. In the future, high purity quartz will be widely used in large-scale and very large-scale integrated circuit manufacturing, optical fiber and cable electronic communication semiconductor, LED lighting manufacturing and packaging, software chip manufacturing materials, new energy solar energy, electronic products and devices, national defense, laser technology, chemical synthesis and precision casting. It is estimated that the demand for high purity quartz and its raw materials will increase by more than 6% year by year.

On the other hand, since 2018, the Sino US trade friction has been escalating, the technology blockade of China by western countries led by the United States has been intensifying, and the external risks of China’s access to overseas resources are gathering. At present, the exploration and evaluation of high-purity quartz raw materials in China is not much, so there is no resource reserve of high-purity quartz raw materials, which can not provide high-purity quartz raw materials with stable quality for production enterprises. The production capacity of high purity quartz in China can not meet the market demand, and the contradiction between supply and demand will gradually become prominent.

Summary

Boron, graphite, fluorite, high-purity quartz and other high-tech minerals have important strategic applications. The rapid rise of strategic emerging industries will rely more and more on high-tech minerals. Therefore, we should carry out and strengthen the planning, investigation and evaluation, exploration, development and utilization of high-tech mineral resources from a strategic height.